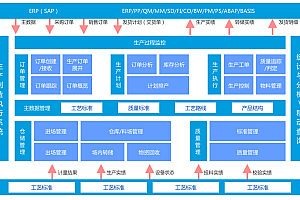

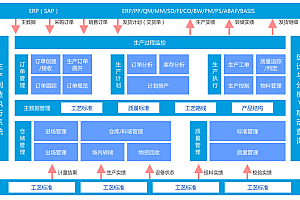

Wanjie Starry Sky Technology’s commercial open-source MES can provide management modules including manufacturing data management, planning and scheduling management, production scheduling management, inventory management, quality management, human resource management, work center/equipment management, tool and fixture management, procurement management, cost management, project board management, production process control, underlying data integration analysis, and upper level data integration decomposition, creating a solid, reliable, comprehensive, and feasible manufacturing collaborative management platform.

Software functional parameters

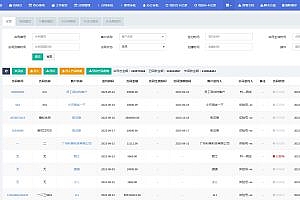

1. Information storage and traceability

Can trace all production process information of the product based on the product flow code. Including: production time and date, key process parameters, supplier code, operators, etc.

2. Quality control and monitoring

By scanning QR codes and using RFID during the processing and assembly process, automatic verification and operation prompts can be provided to prevent worker component assembly errors, product production process errors, etc;

Can indicate the assembly status of the scanned product, whether it is a qualified product, whether it has undergone previous processes, and whether the product model matches, etc; And prompt the operator and lock the equipment when abnormal conditions occur to ensure product quality.

3. WEB Access Module

Remote web access can be achieved through IE to view real-time production site conditions and data, and export relevant data and reports with relevant permissions.

4. Data statistics and analysis module

The data collection server can query and analyze the collected data. At the same time, reports can be made and printed according to requirements.

5. Production Kanban Module

Real time production status data is obtained through an information publishing system, and various production status information (current assembly product model, completion status of job plan, equipment operation status, and abnormal alarm information) is displayed in real time using an information publishing dashboard, providing assistance for visual management of workshop production.

6. Software interface

Having an open interface with the ERP system, it can seamlessly connect with the ERP system.

7. Secondary development

MES software is fully open source software and can be developed again.

Wanjie Starry Sky Technology is a commercial open source MES that can provide source code and free trial. If you need it, please send me a private message.

(Free use of the open source project of Wanjie Starry Sky MES system) (or free download and use from the official website of Baidu Shanghai Wanjie Starry Sky Technology.)