1、Overview of Open Source Systems:

Wanjie Starry Sky Technology offers free MES, open-source MES, commercial open-source MES, the best open-source MES on the market, MES source code, free MES, free intelligent manufacturing system, free production scheduling system, free scheduling system, free quality inspection system, free production planning system, and free digital large screen.

The Java open-source version of the Wanjie Starry Sky open-source MES manufacturing execution system. The open-source MES system includes main functional modules such as system management, workshop basic data management, planning management, material control, production execution, quality management, inventory management, kanban management, and data analysis. Widely used in industries such as automobiles, automotive parts, high-tech electronics, equipment manufacturing, new energy, elevators, home appliances, textiles, electrical, printing, wire and cable, motors, etc.

2、 Open source protocol:

Using AGPL-3.0 open-source protocol

3、 Technical architecture: Springboot2+VUE3+Mysql8+Redis+Minio, also available in SpringCloud version

Demo: Demo Account: https://mesv2.cloudmes.io/

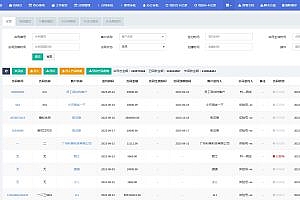

4、 Interface display: partial screenshots

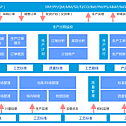

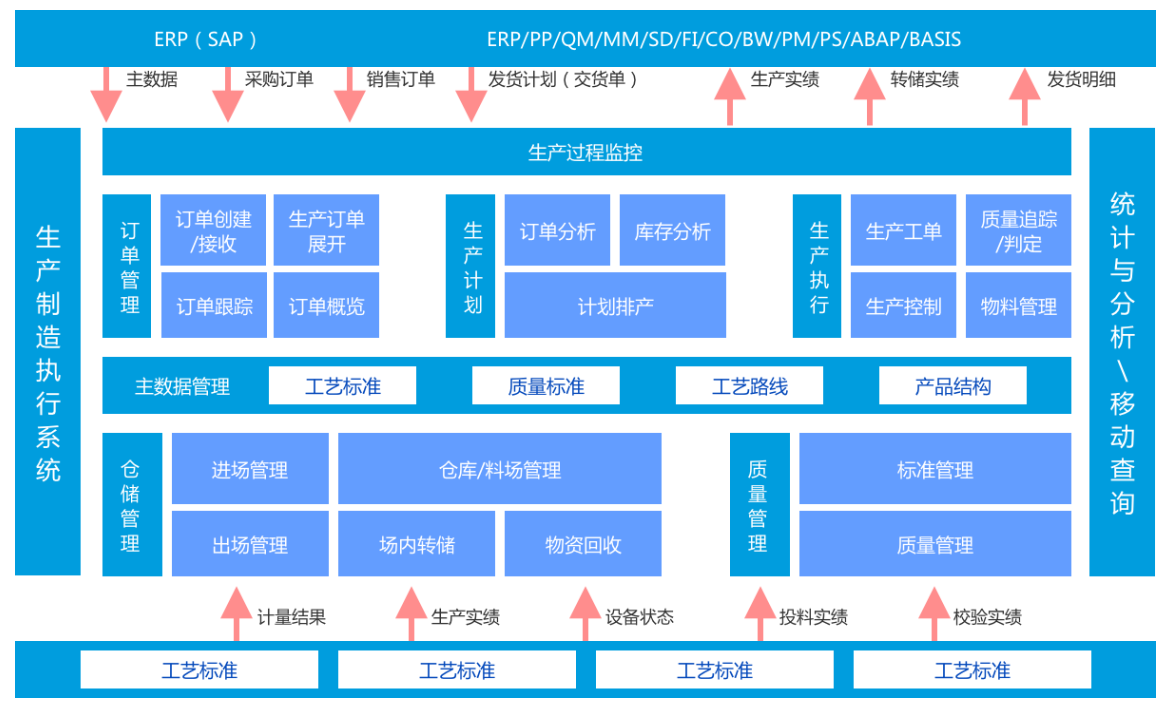

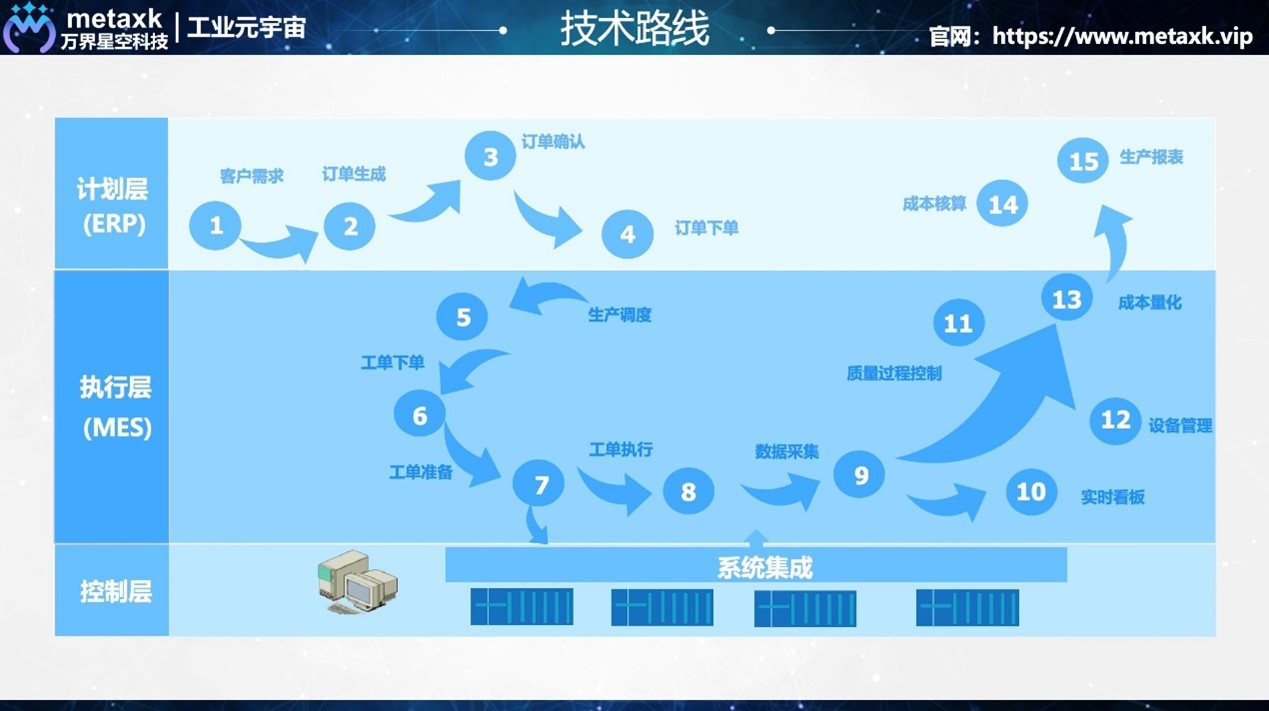

MES system flowchart

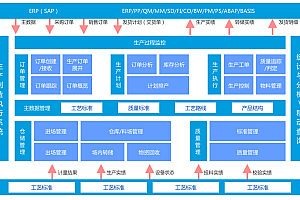

MES functional architecture diagram功能架构图

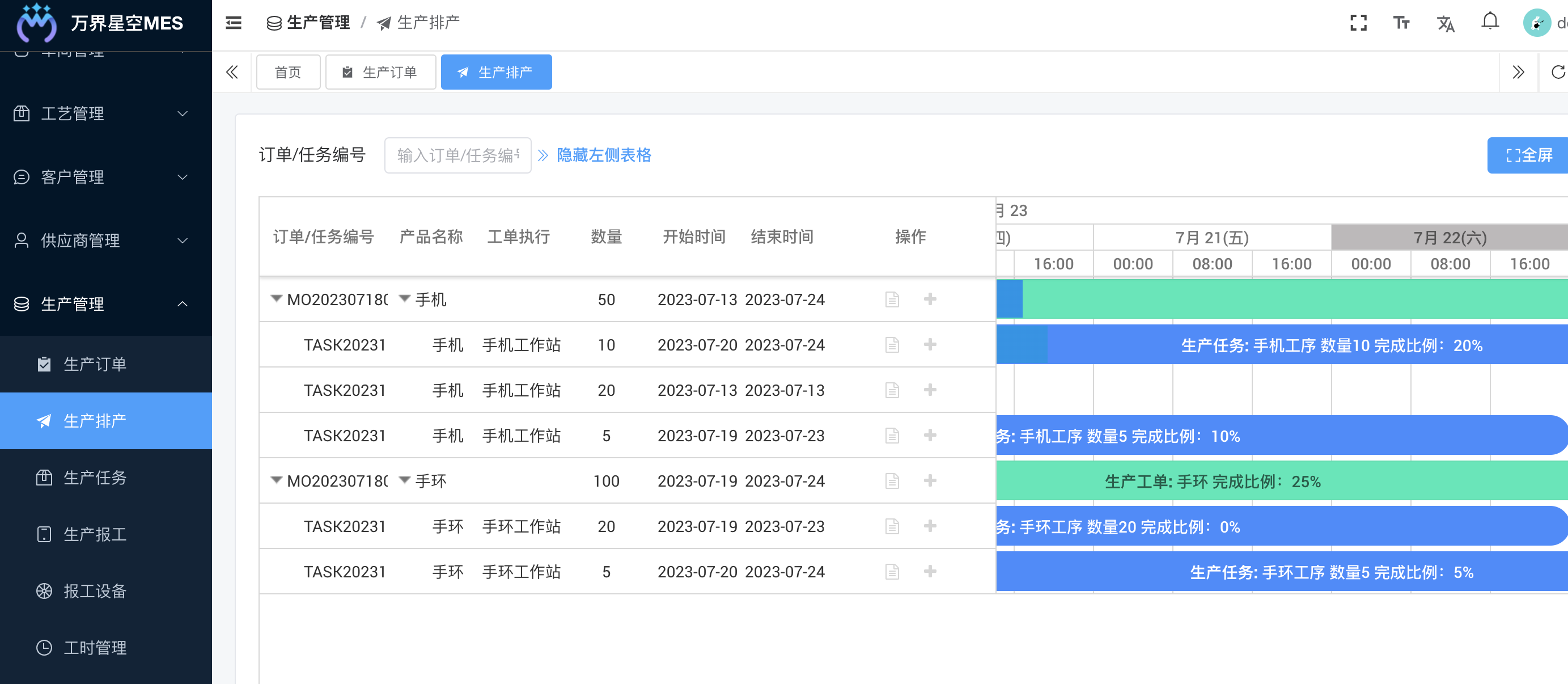

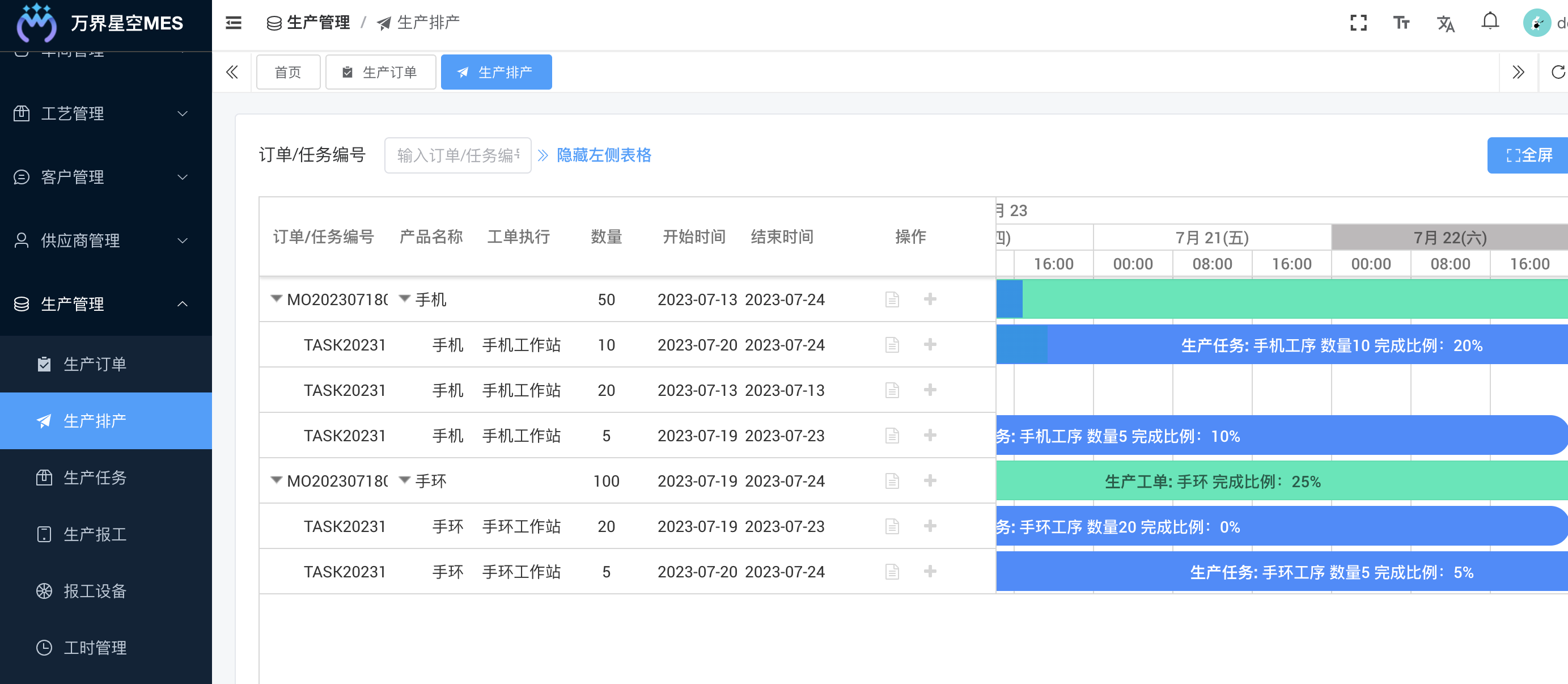

MES production scheduling function diagram

5、 Function Overview:

1. Workshop basic data management: maintenance of work centers, process routes, stations, resources, and operations.

2. Production material control: the management of batch and single item receipt and delivery of materials in the workshop, as well as the management of various types of materials (blanks, semi-finished products, finished products) resources in the workshop.

3. Production planning management: order analysis, material requirement analysis, production scheduling management, and reasonable arrangement of work orders.

4. Production process control: Monitor the production process, automatically correct errors in production, and provide decision support, mainly focusing on the monitored and controlled machines, requiring continuous tracking of the production operation process.

5. Product quality management: management, maintenance, and production batch traceability of non-conforming products.

6. Workshop inventory management: inventory receipt, balance, and inventory history management.

7. Workshop Kanban Management: Workshop Material Consumption Dashboard (including material name, inventory quantity, consumption quantity, balance quantity, inventory limit, safety stock quantity).

8. Data analysis/report management: including production progress reports, workshop inventory reports, production record reports, and SFC assembly information traceability report analysis.

9. System basic management: user information management, role management, menu management

10. Dual traceability of products and raw materials: (supports automatic parsing after QR code scanning and input, and equipment automatically uploads product data)

11. Customization of process flow:

12. Equipment management:

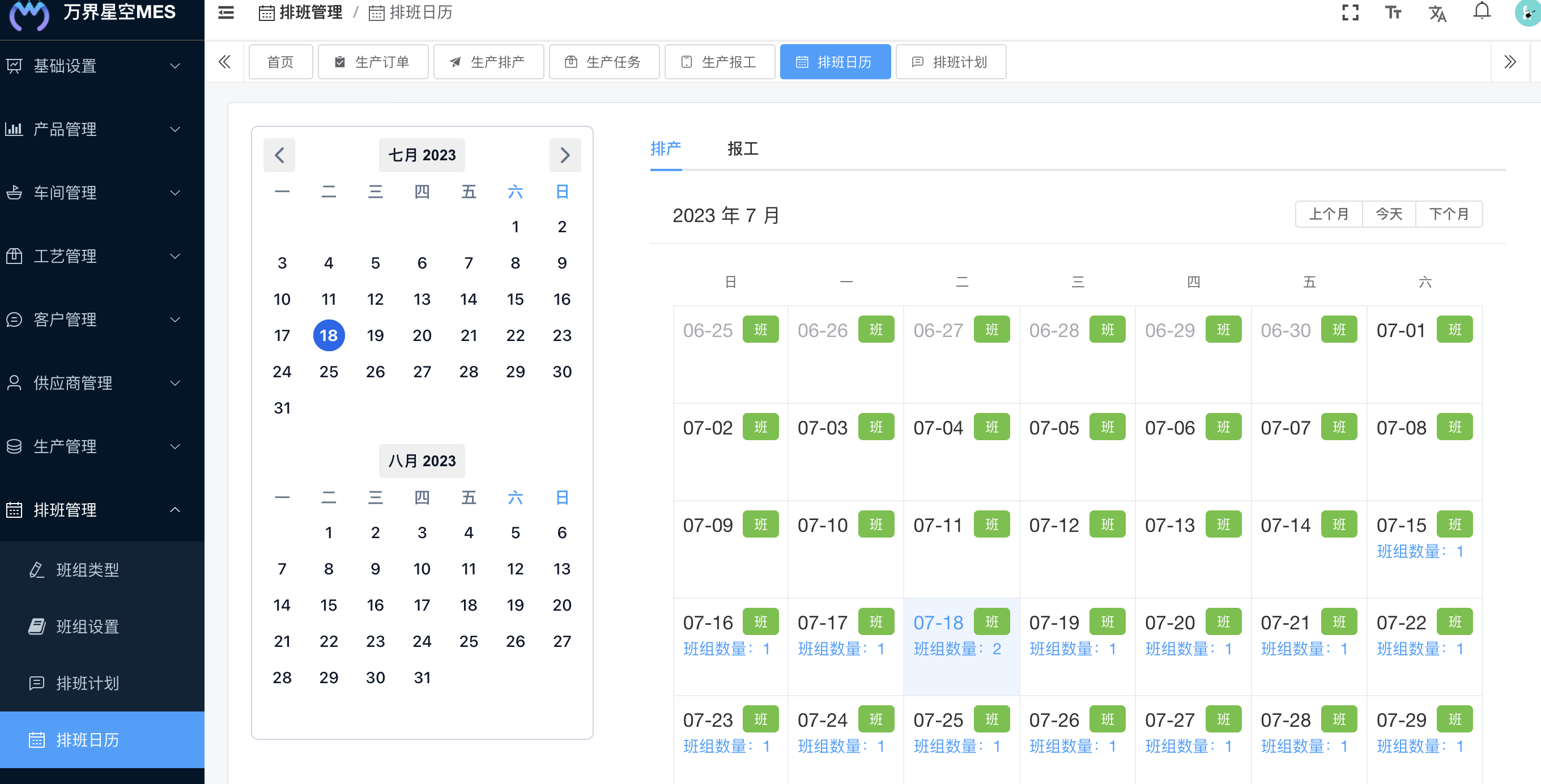

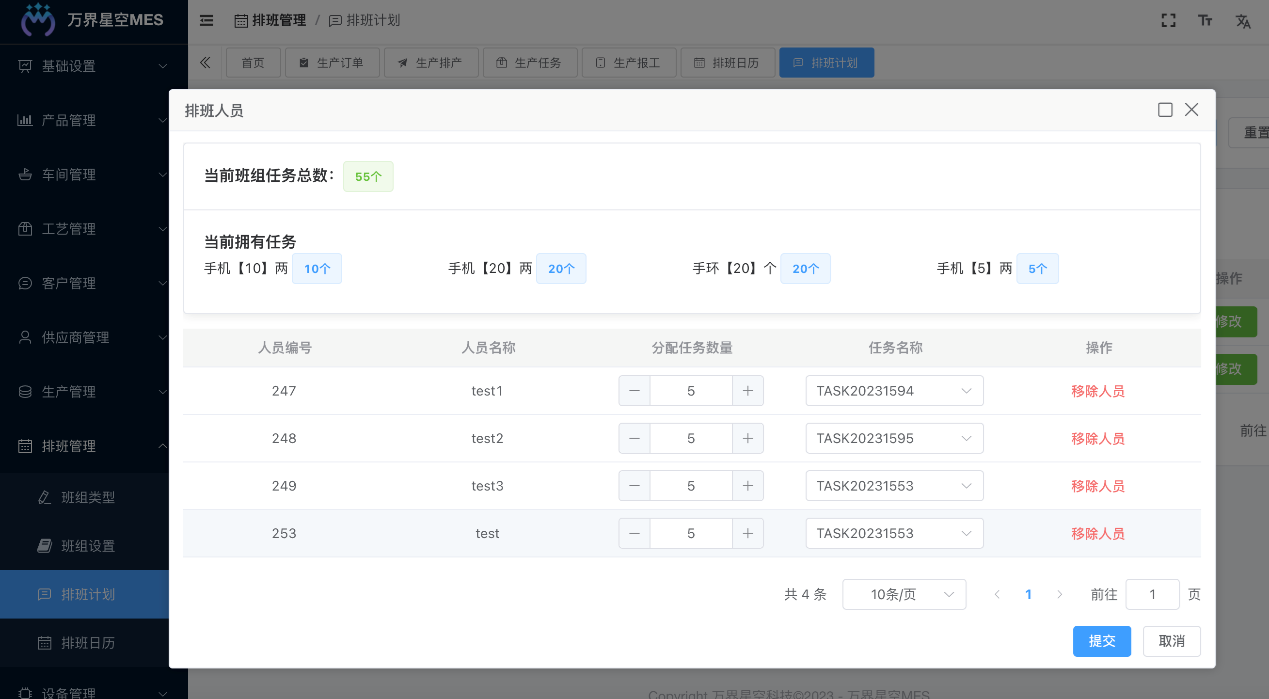

13. Scheduling management:

14. Job reporting: (included in the product management module, automatic job reporting)

15. On site data collection: (PLC equipment, network/serial communication, QR code scanning, etc.),

16. Customer management, supplier management:

17. Visual digital display (order number, production line, team, planned output, actual output, defective quantity, pass rate, completion rate, equipment status and utilization rate, process flow, on-site video, etc.)

18. Compatible with multiple product lines:

19. Backend and ERP integration:

6、 Free download link:

Wanjie Starry Sky Technology focuses on the research and implementation of cloud MES systems, and has successfully helped many enterprises and factories solve internal management problems, effectively improving production efficiency and saving manpower.

(Free use of the open source project of Wanjie Starry Sky MES system) (or click on the official website of Baidu Shanghai Wanjie Starry Sky Technology to download and use for free.)

Download link:

Visit Wanjie Starry Sky Technology Open Source: https://github.com/metaxk-company/free-mes