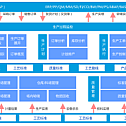

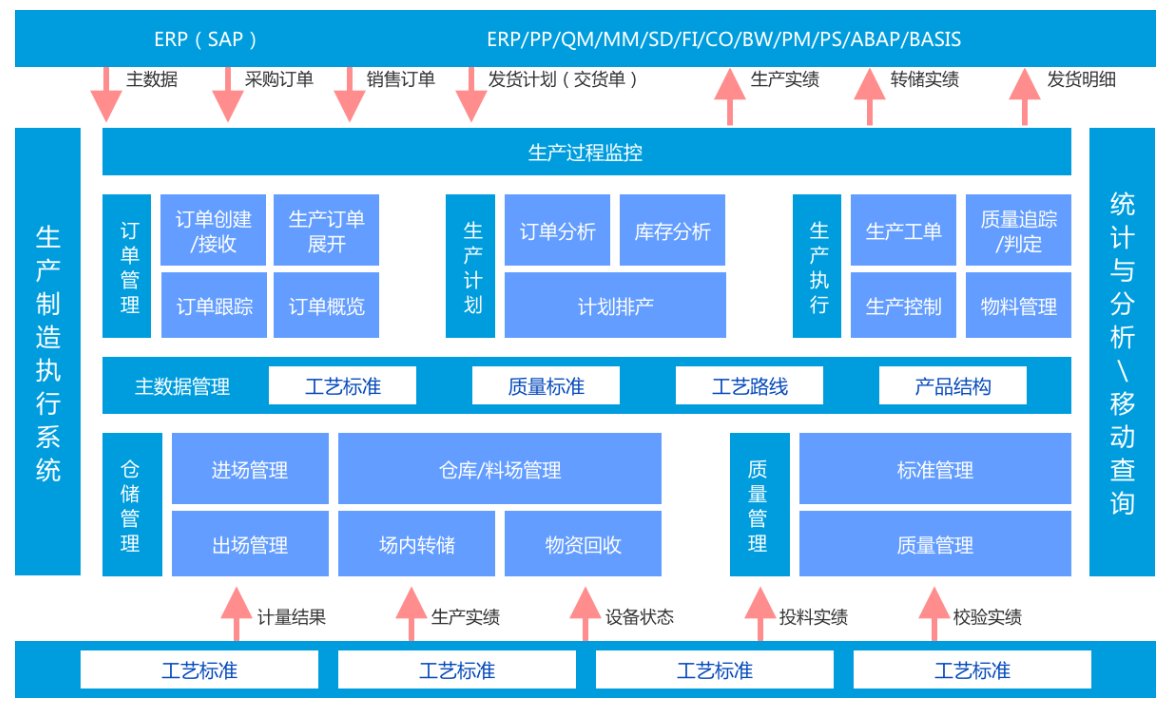

Wanjie Starry Sky Technology’s free MES system helps enterprises achieve production scheduling automation and reduce labor costs. Production planning and scheduling management refers to the process of developing a feasible production plan and arranging production resources and manufacturing activities according to the plan.

It is a key process in manufacturing enterprise management, involving multiple links such as planning, resource management, material procurement, factory layout, production scheduling, etc. It is the core part of the overall production management MES system of the enterprise.

The process of production planning and scheduling

1. Production plan formulation

Firstly, it is necessary to develop a production plan. A production plan is a document developed based on market demand, product type, production capacity, and other factors. It includes information such as production volume, production time, production method, and material list.

In the process of formulating production plans, it is necessary to refer to market demand, historical production data, and supply chain conditions to develop a feasible plan.

2. Preparation of production resources

Preparing production resources is an important prerequisite for developing production plans. Production resources include personnel, equipment, raw materials, etc. Production plans need to be formulated based on actual production resources.

When preparing production resources, factors such as the number and skills of personnel, the quantity and status of equipment, and the supply of raw materials need to be considered.

3. Material procurement

The raw materials and components required in the production plan need to be purchased in advance.

Material procurement needs to be planned and coordinated based on production schedules and supplier conditions. During the procurement process, attention should be paid to factors such as material quality, quantity, and price.

4. Factory layout

According to the production plan, it is necessary to plan the factory layout.

This includes designing and arranging production processes and lines to provide necessary space and resources for production. Layout needs to consider multiple factors such as production efficiency, production quality, and personnel safety.

5. Production scheduling

During the implementation of the production plan, production scheduling is necessary. Production scheduling is the process of arranging production tasks and resources according to a production plan.

Production scheduling needs to be coordinated and optimized based on factors such as production planning, factory layout, and production resources. In the process of production scheduling, it is necessary to pay attention to factors such as the priority of production tasks and the utilization rate of production resources.

6. Production monitoring and optimization

The implementation of production plans requires production monitoring and optimization.

Production monitoring requires real-time monitoring of the production process, timely detection of production problems, and taking corresponding measures. Production optimization requires continuous improvement of the production process to enhance production efficiency and quality.

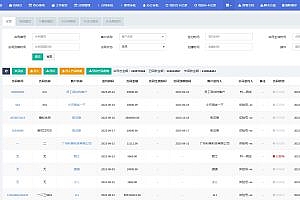

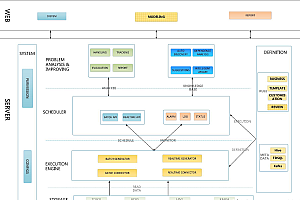

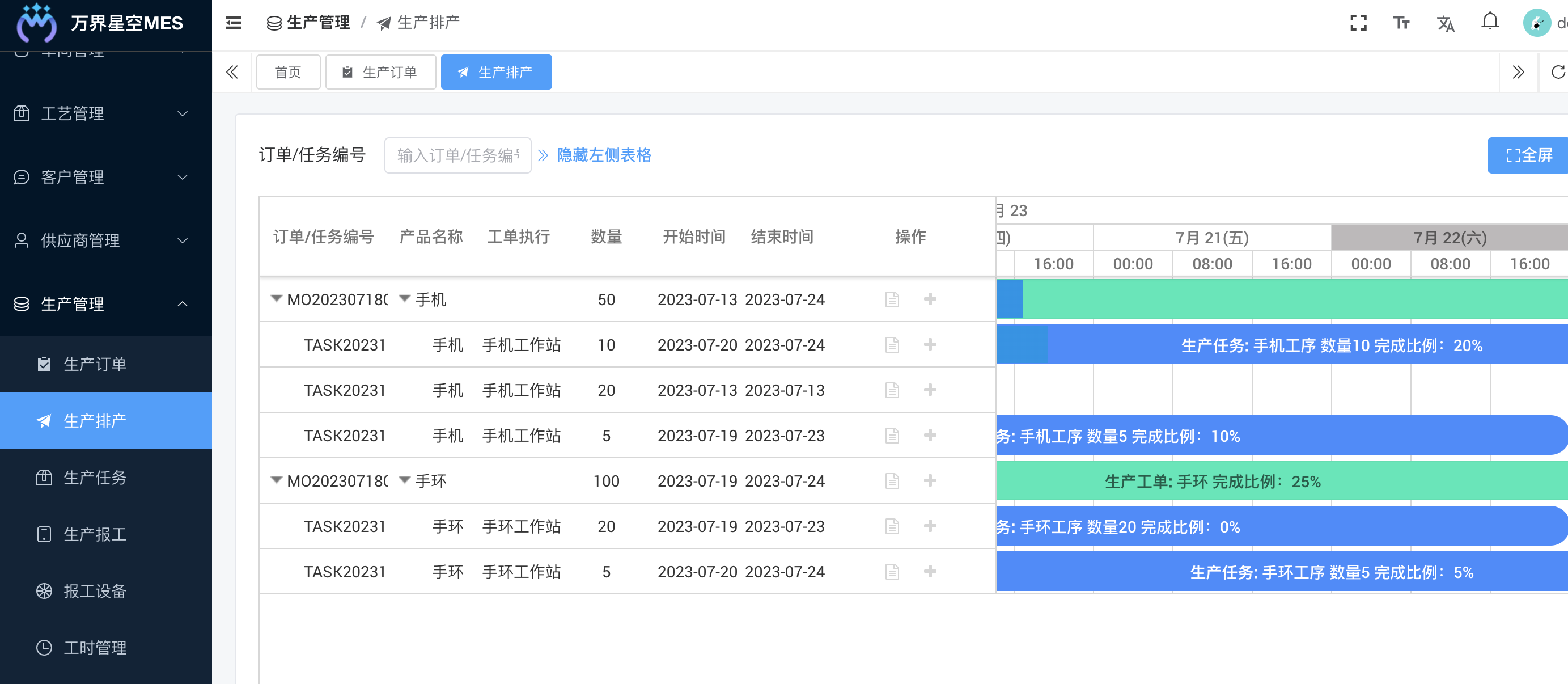

An important function design in MES task “production scheduling” is “scheduling analysis”. Through the analysis of scheduling results, planners can fine tune the automatic scheduling results.

Planners often choose different scheduling strategies based on actual production requirements and production environments, and it is obvious that different scheduling results will be obtained.

According to different priority rules, different scheduling strategies will arrange different orders for pending production, and select different equipment and time periods based on production capacity.

In many cases, it is impossible to meet the optimal production schedule for all work orders. It is often possible to arrange a work order to be produced on a certain equipment that can ensure both delivery time and production efficiency, but it is likely to damage the delivery time of other work orders or lose the efficiency of equipment line switching.

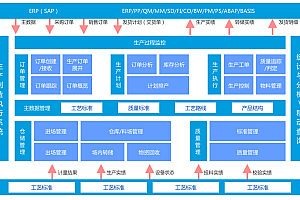

Planning Dashboard: MES Production Planning and Scheduling

1. Order requirements

According to the customer’s order requirements and certain equipment and process constraints, control every production process through MES system settings.

And it is necessary to adjust the production plan according to customer orders at any time. Any changes or adjustments in materials will affect the effectiveness of order execution.

2. High timeliness

How to make products stand out in a fiercely competitive market, in addition to meeting customer needs and ensuring product quality, ensuring product delivery time is also a very important factor.

Therefore, the arrangement and execution of production plans should be organized and implemented according to the requirements of delivery time. Determine the production nodes for each process, emphasize timeliness for each process operation, and ensure the completion of production tasks within the specified time.

3. Integrity of production plan

Due to the fact that customer order requirements run through the entire process of production plan execution, the preparation of each production plan is targeted.

In order to ensure the production volume and delivery time of orders, the arrangement and execution of production plans for each process should also ensure their completeness. It is necessary to minimize the splitting of orders for production, avoid duplicate organization, waste of production resources, and even affect order delivery time.

4. Data synchronization and sharing

The MES system has the advantage of synchronous feedback of logistics and information flow in logistics management, which is conducive to real-time monitoring and adjustment of the production process, thereby reducing process waiting, compressing the quantity of work in progress, strictly controlling intermediate inventory, and minimizing capital occupation.

The MES system of Wanjie Starry Sky Technology quickly and reasonably arranges limited production capacity plans, optimizes plans, achieves optimal production scheduling, improves production efficiency and equipment utilization, and provides effective guidance to the production site.

Wanjie Starry Sky Technology focuses on the research and implementation of manufacturing production management platforms, and has successfully helped many enterprises and factories solve internal management problems, effectively improving production efficiency and saving manpower. Successfully applied in industries such as automotive, high-tech electronics, injection molding, wire and cable, shoe manufacturing, equipment manufacturing, new energy, elevators, home appliances, home furnishings, textiles, printing, electrical, and motors.

Source code address:

Visit Wanjie Starry Sky Technology for free and open source: https://github.com/metaxk-company/free-mes

MES system | Open source MES | Free to use | Free to download | No industry restrictions